- Automatic sorting

- One operator

- Compact design

- Automatisch sorteren

- Eén persoon

- Beperkte opp.

Roto Filling is an automated sorting solution that optimizes the local filling process for pharmacies. It allows you to label medications faster and automatically group them per prescription. This ensures that each logistics staff member is utilized efficiently, and usually, only one operator is sufficient to process the prescriptions of a branch.

How Roto Filling works?

The Roto Filler is an automatic sorting machine designed to label medications and assign them to a temporary prescription location. It consists of a rotating carousel with 44 prescription locations.

Operation is straightforward through a color display, which allows you to continuously monitor the status of each prescription location.

Labeling & Input Procedure

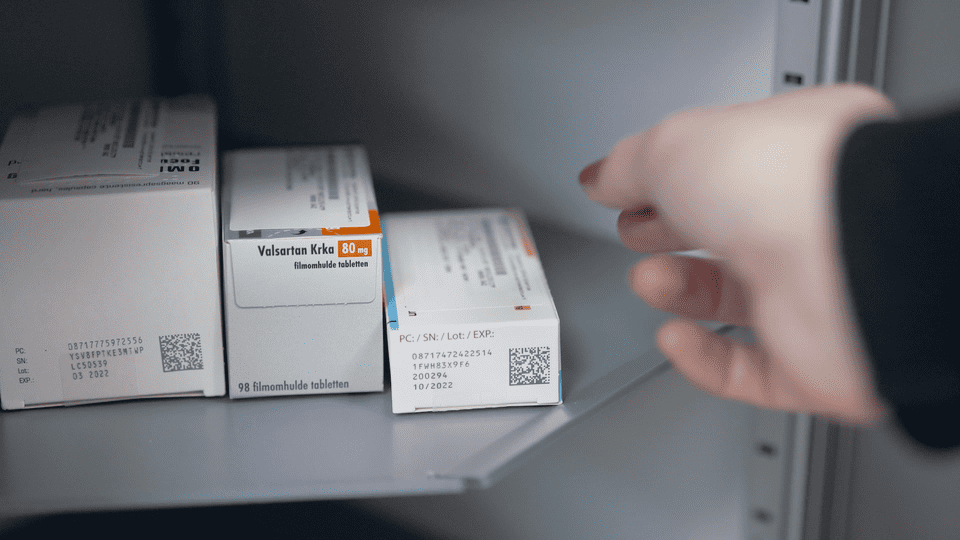

The employee places a tote containing the required medications in the designated position. Then, the employee takes each medication out of the crate one by one and scans the barcode on the medication. Automatically, a label is printed for the respective medicine, which can be affixed to the medication.

Features

During the labeling process, the Roto Filler automatically rotates the correct prescription location towards the employee. Then, the machine indicates through a color display and/or lamp which prescription location the medication should be placed in. This visual guidance helps the employee easily identify and correctly position the medication in the designated receptacle. The color display and/or lamp system streamlines the process, reducing the chances of errors and ensuring efficient medication sorting.

Is Roto Filling profitable for your pharmacy?

Check on errors

Afterwards, a sensor detects whether the employee has placed the medication in the correct prescription location. If this is not the case, the system stops. This ensures the correct procedure and quality of the prescription, allowing logistical staff to handle the task with confidence.

Packing of orders / prescriptions

Once all the medications are distributed, the prescription locations can be cleared. The employee can sit down and use the control display to rotate the prescription locations towards themselves. The same display also indicates whether a prescription is ready to be packaged. This allows for a convenient and efficient process of clearing the prescription locations and preparing the medications for packaging.

Apply address label

Each prescription location has a barcode, and with the barcode scanner, you can quickly print an address label. Medications are then taken from the prescription location and packaged. After affixing the address label, the prescription is ready to be handed over to the customer! This streamlined process ensures efficient prescription dispensing and accurate labeling for customer convenience.

Advantages of Roto Filling?

Improvement of work comfort

Because Roto Filling operates based on the product rather than the patient, it no longer matters how you supply the medications. You can randomly pick a medication and scan the barcode. Roto Filling will then find the corresponding prescription and automatically rotate the correct prescription location towards you.

Saving of 4 to 6 employees

The RF machine essentially requires only 1 employee for the sorting work. In combination with an automatic label printer, which separates the label paper automatically, the input speed reaches between 500 to 600 items per hour (equivalent to 180 prescription lines per hour). This high input speed and the efficiency of the sorting process make the RF machine a valuable asset in optimizing prescription handling within the pharmacy.

Enhancing efficiëncy

All manual actions take place at the front of the machine. This allows a person to label the medications, place them in the designated prescription locations, and package the medications with address labels all from the same position. The convenience of having all these tasks accessible from the front of the machine streamlines the process and maximizes efficiency for the employee handling the prescription sorting and packaging tasks.

Strong simplification of the sorting process.

The nature of the tasks is simplified by the Roto Filler, and automatic checks are performed on manual actions, allowing the tasks to be carried out by logistics staff as well.

Compact machine for every Pharmacy

Due to limited and costly space in pharmacies, we have tailored the dimensions of the Roto Filler accordingly. With a workspace of only 2m², we offer the most compact sorting solution in the market. This ensures efficient use of space while providing the necessary automated sorting capabilities for pharmacies.

Reliable industrial technology

Roto Filling is entirely constructed using industrial-grade components, and simple mechanical solutions have been employed in its design. This makes the Roto Filler a straightforward, robust, and reliable machine. The use of durable and reliable industrial components ensures the smooth operation and longevity of the machine, providing pharmacies with a dependable sorting solution for their medication handling needs.